Threads: types and designations

for information

How to reduce wear stress in metal components

16 October 2018

Brass: uses and properties

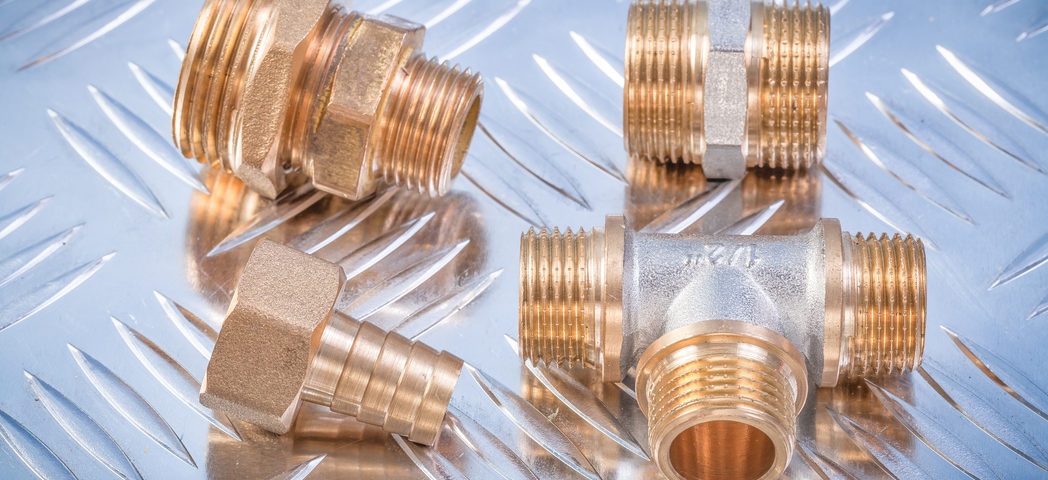

19 December 2019Threads are a constant-section helix-shaped prominence made on a cylindrical surface. MPT Srl produces many types of thread such as gas, metric and left-hand threads. Our products are mainly used in the rubber hose holder sector.

Thread types

How does one distinguish between different thread types? Usually a distinction is made on the basis of the profile shape, and each of them meets the different requirements of functionality and service. There therefore exist:

1 – Triangular profile threads;

2 – Non-triangular profile threads.

Triangular profile threads are in turn subdivided as follows:

ISO metric threads: all thread elements are measured in millimetres.

Non-metric threads: all or some of the elements are expressed in units of measurement other than millimetres or in a conventional manner. The main non-metric threads are Whitworth and gas.

Non-triangular profile threads are divided into:

Trapezoidal profile: these threads have a symmetrical isosceles trapezoidal profile.

This profile type has replaced the square or rectangular profile threads which were previously in use. The trapezoidal profile is better because it has greater strength and ease of entry. This is a profile which is usually used for manoeuvring screws, i.e. when, by rotating the screw or the screw nut, a reciprocal movement of two mechanical parts is to be obtained. This applies in particular when dealing with large load transmission screws.

c: this is an asymmetrical thread which is used as the manoeuvring screw in the case of large forces, with a constant direction. Two types are standardized: normal sawtooth and fine sawtooth. The axial clearance between the screw and the nut is considerable and the supporting side of the screw has an inclination of 3°.

Thread designation

How is a thread designation carried out? The main parameters are:

- A literal symbol identifying the thread;

- the nominal diameter, which coincides with the outer diameter d of the screw measured at the crest of the thread, and with the diameter D of the nut, measured at the bottom of the thread. It is expressed in millimetres or inches. In the case of gas threads, this diameter corresponds to a conventional diameter.

- the pitch, which is the distance between the crests of two consecutive threads or, more generally, between two corresponding points on parallel sides, measured parallel to the axis of the helicoid.

The pitch is proportional to the height of the thread. It is expressed in mm when different from the nominal diameter (fine thread). - The number of threads per inch, in the case of American and Whitworth threads;

- the number of divisions if greater than one;

- the direction of the helix, if left: sin. (sinistro > left) or LH (Left Hand).

Characteristics of thread types

Below are some of the main characteristics of triangular profile threads.

ISO metric threads

The ideal profile of ISO metric threads is an equilateral triangle.

The nominal profile of the nut in relation to the base profile has truncations, both in the crest and at the bottom, while the nominal profile of the screw has truncations in the head and roundings at the bottom.

Finally, the actual profile of the screw and the nut always has roundings at the bottom.

Whitworth threads

The ideal profile of Whitworth threads is an isosceles triangle with a vertex angle of 55°.

The actual profile is rounded compared with the base profile. It should be noted that the dimensions by which the shape of the thread is measured (parameter H) are pitch functions.

Compared to the ISO system, there therefore exists a different profile angle together with rounding, also on the crest. In addition, for the same diameter the Whitworth pitch is larger than the large ISO pitch.

Whitworth threads formed the basis of many thread systems (particularly gas threads) and were the first to be standardized in 1841.

Gas threads

Neither the ISO metric threads nor the Whitworth threads guarantee tightness between the screw and the nut when the passage of fluids is concerned, while the gas threads do so. In fact, this name derives from their initial use in gas pipelines. The profile of these threads is the same as that of the Whitworth threads, but the pitches are finer. The nominal diameter is conventional: it refers to the theoretical internal diameter of the pipe on which the thread is used.