THE LABORATORY – Precision turned parts

- Traditional Control Instruments, regularly checked and calibrated;

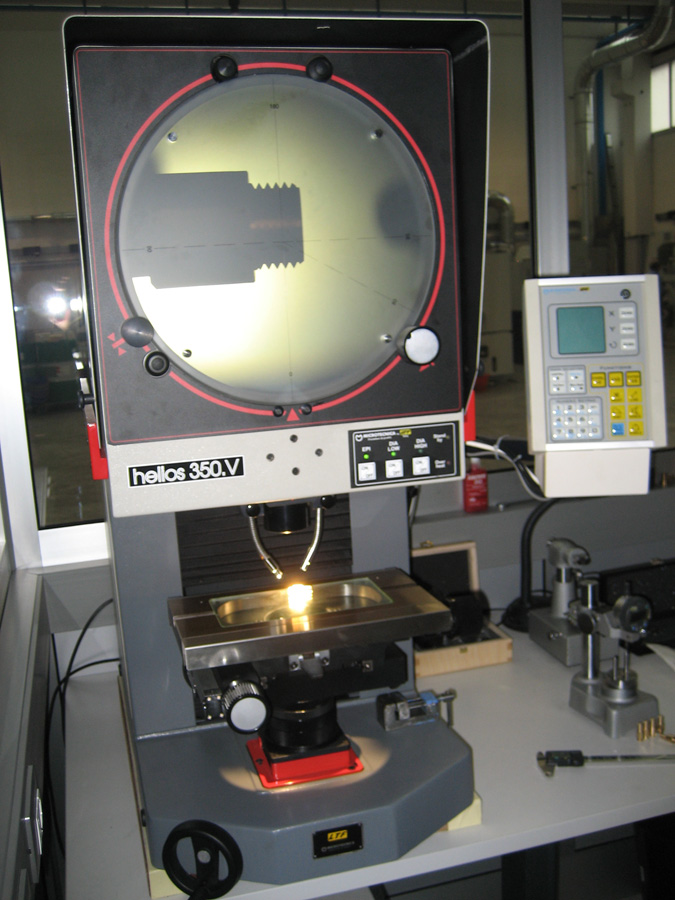

- New digital equipment, with automatic performance monitoring;

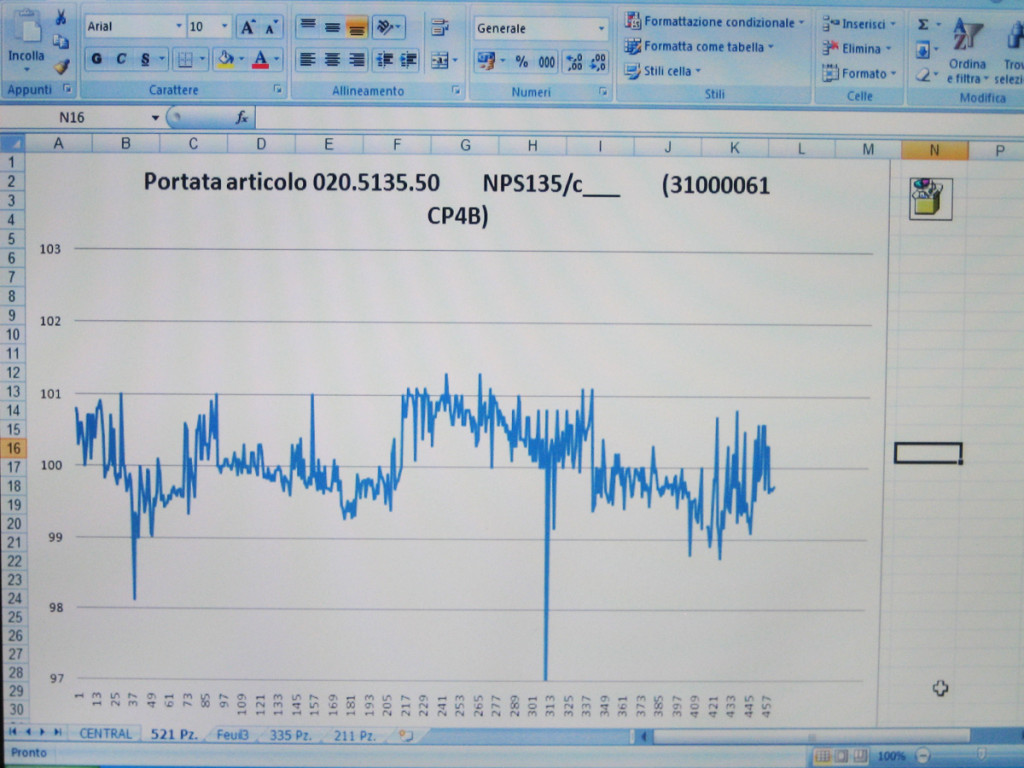

- Information and data recording in a specific testing management system, allow us to maintain a consistent level of quality and efficient tracking and statistical analysis of the collected data.

Quality Assessment tools:

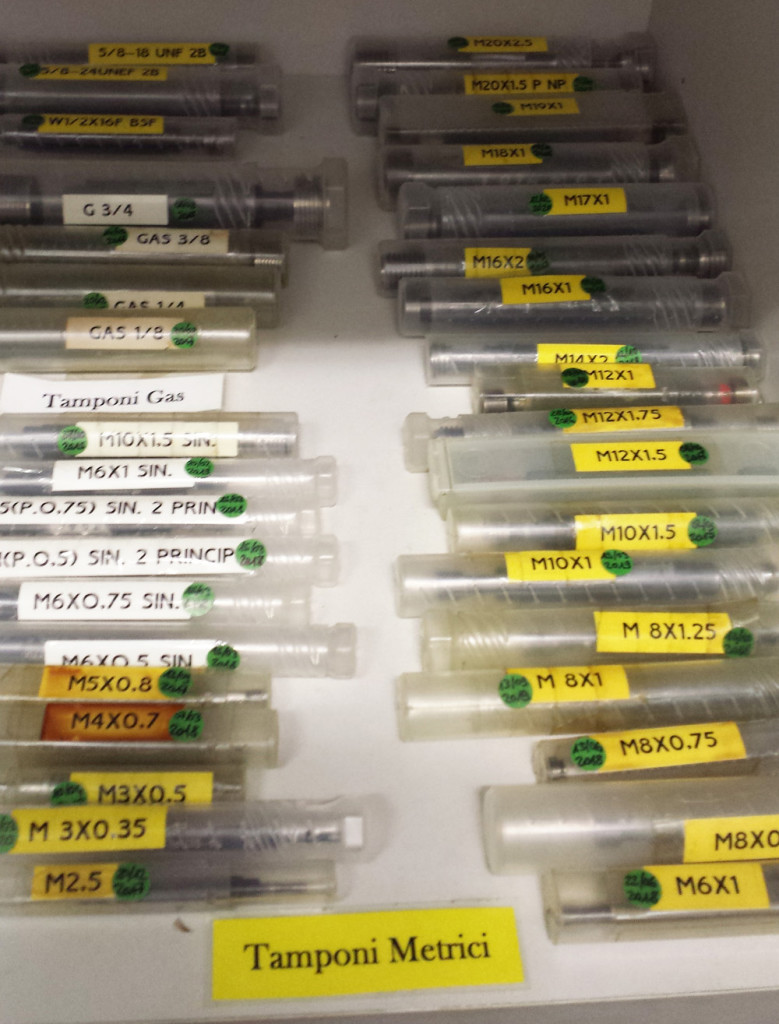

Other Assessment tools:

- Bore gauge – Mitutoyo interfaced with the PC for holes ø0.5 to ø20

- Comparators Mitutoyo

- Micrometers Mitutoyo

- Digital Calipers Mitutoyo and Sylvac

- Gas Control gauges, metric, NPT, UNF, UNS, and DIN 2999 conical ISO7

- Control plugs, gas and metric

- Comparison setting pings

- Digital Roughmeter Bocchi

On customer request certificates of measurement, with material analysis, can be issued.